Uhlolojikelele

Ithuluzi lomshini we-CNC wukusetshenziswa okudidiyelwe komshini, ugesi, ihydraulic, pne-umatic, microelectronics nolwazi kanye nobunye ubuchwepheshe njengobunye bemikhiqizo yokuhlanganisa i-electrom-echanical, emishinini yokukhiqiza eyimishini eguquguqukayo, yendawo yonke, enembayo ephezulu, ephezulu. ukusebenza kahle "okuguquguqukayo" imishini yokukhiqiza okuzenzakalelayo, izocubungula imisebenzi ehlukahlukene nezinyathelo ezidingekayo kanye nokuma nosayizi we-workpi-ece, ngekhodi yedijithali, Ngokusebenzisa indlela yokulawula ingene kudivayisi yokulawula izinombolo, idivayisi yokulawula izinombolo ukuya kulwazi lokufakwayo. ukucubungula nokubala, uhlelo lomshini wokulawula umyalo kanye nezingxenye zokushayela, ukucutshungulwa okuzenzakalelayo kwe-workpiece edingekayo. Izinga lobuchwepheshe lamathuluzi omshini we-CNC kanye namaphesenti alo ekuphumeni nasekubeni okuphelele kwamathuluzi emishini yokusika insimbi kungenye yezinkomba ezibalulekile zokulinganisa izinga eliphelele lokuthuthukiswa komnotho kazwelonke kanye nokukhiqizwa kwezimboni zezwe. Eminyakeni yamuva nje, isabelo samathuluzi omshini we-CNC emabhizinisini aseShayina siye sakhula unyaka nonyaka, futhi sisetshenziswe kakhulu emabhizinisini amakhulu naphakathi nendawo, futhi ngokuvamile sisetshenziswa emabhizinisini amancane naphakathi nendawo ngisho. amabhizinisi ngamanye.

Izidingo zenqubo ye-CNClathe

- Uma i-workpiece icutshungulwa yi-CNC lathe, inani lokuphakelayo likhulu, isivinini se-proce-ssing siphansi, futhi inqubo yomshini inomthwalo womthelela ngenxa yokungalingani kwendawo yokusebenza.

- I-Lathefinishing, inani lokuphakelayo lincane, ukuze kuqinisekiswe ukusebenza kahle kokucubungula, isivinini sokucubungula siphezulu.

- I-spindle motor idingeka ukuthi ibe nesivinini esiphansi kanye nokukhishwa kwetorque ephezulu, futhi iyi-stab-le, futhi ingagijima ngesivinini esikhulu.

- Ukwamukela amasignali e-analog kudinga umugqa ophezulu kanye nokuphazamiseka komthwalo ophansi.

- Umsindo we-Themotor mncane, futhi ukuphazamiseka kwemishini ye-automation yesistimu kuncane.Sheshisa futhi wehle ngesivinini kancane ngangokunokwenzeka.

Izinzuzo zemikhiqizo yochungechunge lwe-CNClathe KD600

I-Kd600 yochungechunge lwe-vector inverter esebenza kahle kakhulu isebenzisa ubuchwepheshe obuthuthukisiwe bokulawula ukugeleza, i-torque ye-motor ngesivinini esiphansi inkulu, ukunemba kwesivinini kuphezulu, intengo inengqondo, umsebenzi uphelele, ngokucubungula ukwehluleka kwamandla kanye nokulandelela isivinini bese uqala futhi ukusebenza. , ukuqinisekisa ukuthi uhlelo lokufeza indlela yokusebenza eqhubekayo, ukuqinisekisa ukuthi injini isebenza ngendlela esezingeni eliphezulu kakhulu, ngakho-ke, Ukusebenzisa uchungechunge lwe-vector inverter esebenza kahle kakhulu ye-KD600 esikhundleni sesistimu ye-AC servo yokuphotha kuyisinqumo esingcono kakhulu embonini yamathuluzi omshini. I-inverter yochungechunge lwe-KD600 inezici ezilandelayo:

- Ubuchwepheshe obuhlukile obubuthakathaka bokulawula kazibuthe: bungaba ukulawula okuhle kwenjini ye-torque enkulu, ingasebenza ngo-0 ~ 600Hz.

- Isivinini sokuma esisheshayo: ubuchwepheshe bokumisa ukwehla kwamandla kazibuthe bungenza injini yehle futhi ime ngesikhathi esifushane.

- Ukunemba kwesivinini nokuzinza: umugqa wokumisa isivinini muhle, ukunemba kokuqina kwesivinini kuphezulu, futhi ukuguquguquka kwesivinini kungaphakathi kwe-5/1000 lapho umthwalo ushintsha.

- Ukusebenza okuhle kakhulu kwemvamisa ephansi: I-algorithm yokulawula i-vector elungiselelwe i-PG-free, imvamisa ephansi engu-1Hz ifika ku-150% okukhiphayo okulinganiselwe kwe-torque, ukuqinisekisa amandla aqinile okusika ngesikhathi sokucubungula okungenalutho.

- Nikeza ngezindlela zokufaka amafrikhwensi amaningi: imithombo yamandla kagesi emi-2 0 ~ 10V noma -10V ukuya ku-+10V okokufaka, umthombo wamanje ongu-1 4~20mA noma okokufaka okungu-0~20mA.

- Ububanzi obubanzi bokusebenza kwamandla kagesi wegridi: Idizayini yokunikeza amandla okushintsha okuthuthukile ingasetshenziswa ezindaweni ezihlukahlukene zegridi.

- Inqubo yokukhiqiza enhle kakhulu: sebenzisa inqubo eyingqayizivele yokujiya, ipayipi lomoya lihlukaniswe ngokuphelele ne-PCB yangaphakathi, futhi likwazi ukuzivumelanisa nezimo eziqinile nemvelo enokhahlo njengothuli lwensimbi, igesi egqwalayo kanye nomswakama.

- Isekhethi yokumunca ukuvuza eyakhelwe ngaphakathi inciphisa kakhulu ukushaqeka kukagesi emzimbeni womuntu lapho indlu yemishini ishajwa.

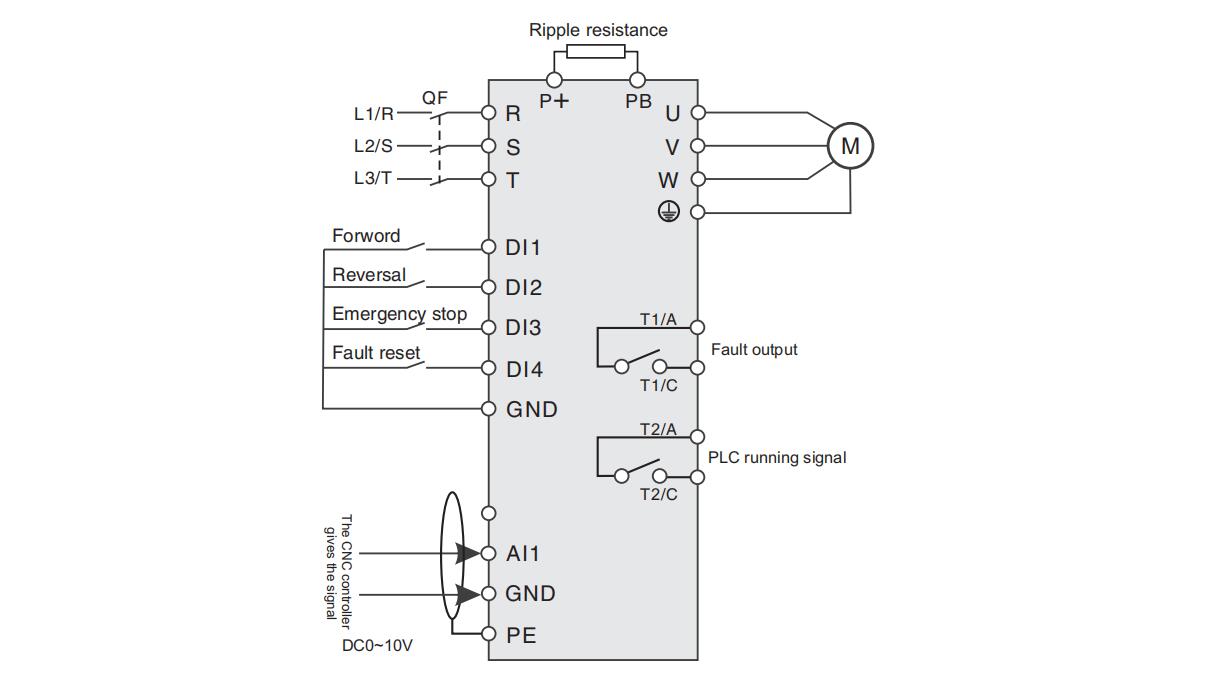

Umdwebo wezintambo eziyisisekelo

Izilungiselelo zepharamitha nencazelo

| Ukulungiselelwa kwepharamitha | Iziyalezo | Ukulungiselelwa kwepharamitha | Iziyalezo |

| P0-03=1 | Ayikho imodi yevekhtha ye-PG | P4-01=11KW | Amandla alinganiselwe emoto |

| P0-04=1 | Itheminali yangaphandle iqala noma iyama | P4-02=380V | I-voltage elinganiselwe ye-motor |

| P0-06=2 | Inani le-analog AI1 linikeziwe | P4-04=22.6A | Isilinganiso samanje semoto |

| P0-14=150 | Umkhawulo wokuvama kokuphumayo | P4-05=50Hz | Ikalwe imvamisa yemoto |

| P0-16=150 | Umkhawulo wokusebenza okuphezulu | P1-06=1435RPM | Ijubane lemoto elilinganiselwe |

| P0-23=1.0 | Isikhathi sokusheshisa | P6-00=2 | Okukhipha iphutha |

| P0-24=0.8 | Isikhathi sokunciphisa | P6-02=1 | Isiguquli semvamisa siyasebenza |

| P5-00=1 | Ukugijima phambili | P5-01=2 | Ukugijima okuhlanekezelwe |

| P4-01~P4-06 amapharamitha emoto sicela ufake ngokunembile | |||

Umphumela wokulungisa iphutha

Kufakazelwe ukuthi i-KD600 yochungechunge olusebenza kakhulu lwe-vector frequency converter ingahlangabezana ngokugcwele nezidingo zokulawula ukuphotha kwethuluzi lomshini. I-KD600 yamukela imodi yokulawula i-vector ehamba phambili ye-PG-free, engakwazi ukukhipha ngokushelela i-torque engu-150% ngisho nangaphansi kwejubane eliphansi (imvamisa ephansi) ukuze ihlangabezane nezidingo zokucubungula izingxenye ezihlukene, futhi ingakwazi ukufaka esikhundleni ngokuphelele isakhiwo se-spindle esinama-rolling, kanye nalokhu isakhiwo silula, sihlangene, futhi singafinyelela umthethonqubo wejubane ongenasinyathelo. Ijubane lale nto yokuphotha lilawulwa isignali ye-analog yangaphandle ukuze kulawulwe imvamisa yokuphumayo ezinqubweni ezihlukene zokucubungula (isb. Ukugoqa, ukuqeda, njll.) kudinga isivinini esihlukile, ngalesi sikhathi, uhlelo lokulawula izinombolo lungakhipha amasignali ahlukene kagesi we-analog i-inverter ukuze kuzuzwe isivinini esihlukile, futhi isignali yokuqala nokumisa nayo ilawulwa uhlelo lokulawula izinombolo, oluthuthukisa izinga lokuzenzakalelayo futhi lwandise impilo yesevisi yethuluzi.

Isikhathi sokuthumela: Nov-17-2023