Uhlolojikelele

Eminyakeni yamuva nje, umnotho waseShayina uye wathuthuka ngokushesha, izinkinga zamandla ziye zaba indololwane eyinhloko yokuthuthukiswa kwemboni, futhi ngokukhuphuka ngokushesha kwamanani kagesi, ukuncintisana okunamandla emakethe yasekhaya, ukongiwa kwamandla kuye kwanda. ibe inkinga enkulu ebhekene nokuthuthukiswa kwama-ind-ustries amaningi, ikakhulukazi okunye ukusetshenziswa kwamandla kuyizimboni ezinkulu ezifana ne-petroleu-m, amakhemikhali, imithi, i-metallurgy, ukukhiqiza, ukuvikelwa kwemvelo, umasipala-pal nezinye izimboni. Ngokusho kwedatha, umthamo ophelele wamamotho kagesi aphezulu naphansi eChina ungaphezu kuka-35000MW, iningi lawo lilayisha amaphampu abalandeli, futhi iningi lawo lisebenza ngokusetshenziswa kwamandla okuphezulu nokusebenza kahle okuphansi.

I-fan evamile, uhlelo lwephampu iningi le-valve yokulungisa ukugeleza kwamanzi noma ingcindezi, ukuphambanisa lo mthethonqubo ukukhulisa ukulahlekelwa kwenethiwekhi yamapayipi, kudle amandla amaningi ngezindleko, ngakho-ke, kubangela ukuchithwa kwamandla kagesi nakanjani. Futhi ngenxa yokuthi umklamo, uhlelo luklanyelwe ngokuhambisana nomthwalo omkhulu, ekusebenzeni kwangempela, isikhathi esiningi uhlelo alukwazi ukusebenza esimweni somthwalo ogcwele, kukhona i-surplus enkulu, ngakho-ke kukhona amandla amakhulu okonga amandla. .

Kusetshenziswa idivayisi yokulawula isivinini sokuguqulwa kwemvamisa ye-KD600, ngokushintsha isivinini sefeni, ukuze uguqule ivolumu yomoya wabalandeli ukuze uhlangabezane nezidingo zenqubo yokukhiqiza, futhi ukusetshenziswa kwamandla okusebenza kuyikona okusindisa kakhulu, inzuzo ephezulu kakhulu ebanzi. Ngakho-ke, ukulawulwa kwesivinini esishintshashintshayo kuwuhlelo lokulawula isivinini olusebenza kahle futhi olufanele, olukwazi ukubona ukulawulwa kwesivinini esingenasinyathelo sefeni, futhi lungakha kalula uhlelo lokulawula iluphu evaliwe ukuze kuzuzwe ingcindezi engaguquki noma ukulawula ukugeleza okuqhubekayo.

Ukuguqulwa kwemvamisaIsimiso sokulawula isivinini sohlelo lokonga amandla

Ngokomgomo we-fluid mechanics, ubudlelwano phakathi kwamandla e-shaft P kanye nevolumu yomoya Q kanye nomfutho womoya H wefeni eshayelwa yinjini yokungeniswa yilo kanje:

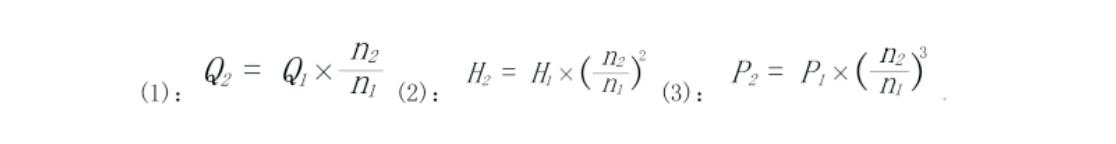

“Q*H Uma ijubane lemoto lishintsha lisuka ku-n1 liye ku-n2, ubudlelwano phakathi kwe-Q, H, P kanye nesivinini bumi kanje:

Kuyabonakala ukuthi ivolumu yomoya Q ilingana nesivinini n semoto, futhi amandla e-shaft adingekayo P alingana nekhiyubhu yejubane. Ngakho-ke, lapho i-80% yevolumu yomoya elinganisiwe idingeka, ngokulungisa isivinini se-motor kuya ku-80% wejubane elilinganiselwe, okungukuthi, ukulungisa imvamisa ku-40.00Hz, amandla adingekayo azoba ngu-51.2% kuphela wangempela.

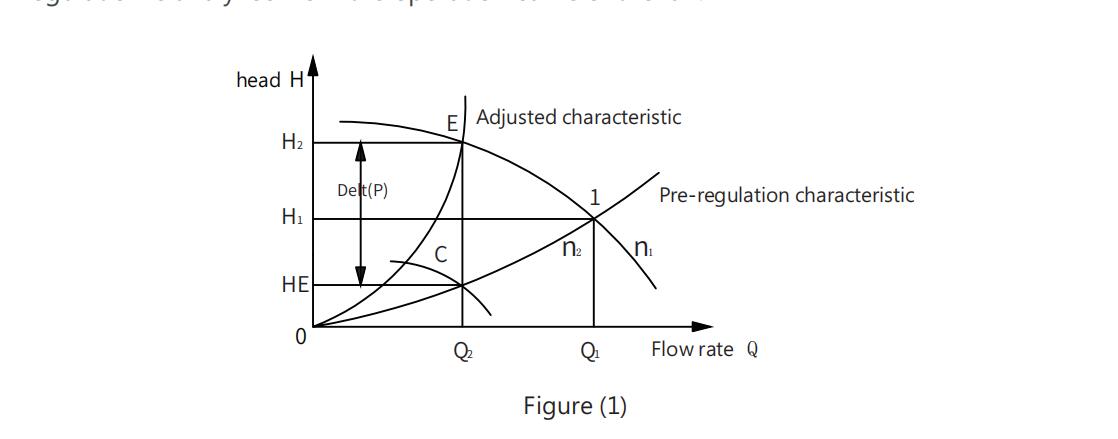

Njengoba kuboniswe Emfanekisweni (1), umphumela wokonga amandla ngemva kokwamukela ukulawulwa kwesivinini esishintshashintshayo kuyahlaziywa kusukela ejikeni lokusebenza kwefeni.

Lapho umthamo womoya odingekayo wehla usuka ku-Q1 uye ku-Q2, uma indlela yokulungisa i-damper yamukelwa, ukumelana kwenethiwekhi yepayipi kuzokwanda, ijika lenethiwekhi yepayipi le-charact-eristic lizokhuphuka, indawo yokusebenza yesistimu izoshintsha ukusuka endaweni. A ukuya endaweni yesimo sokusebenza esisha B, namandla e-shaft adingekayo P2 ahambisana nendawo H2×Q2. Uma imodi yokulawula isivinini yamukelwa, isivinini se-fan siyehla sisuka ku-n1 siye ku-n2, izici zenethiwekhi azishintshi, kodwa ijika lesici sabalandeli lizokwehla, ngakho iphuzu layo lesimo sokusebenza lisuswa kusuka ku-A kuya ku-C. edingekayo shaft amandla P3 ilingana nendawo HB×Q2. Ngokwethiyori, i-shaft power Delt(P) elondoloziwe ilingana nendawo ye-(H2-HB) × (CB).

Uma kucatshangelwa ukuncishiswa kokusebenza kahle ngemva kokuncipha kanye nokulahlekelwa okwengeziwe kwedivayisi yokulawula isivinini, ngezibalo ezingokoqobo, abalandeli bangonga amandla ngokulawula isivinini esifinyelela ku-20% ~ 50%.

Inzuzo yokulawula isivinini esishintshashintshayo

- Isici samandla sohlangothi lwenethiwekhi siyathuthukiswa: lapho i-motor yasekuqaleni iqhutshwa ngokuqondile imvamisa yamandla, isici samandla singaba ngu-0.85 ekulayisheni okugcwele, futhi isici samandla esisebenzayo siphansi kakhulu kuno-0.8. Ngemuva kokwamukela uhlelo lokulawula isivinini sokuguqulwa kwe-frequency, isici samandla sohlangothi lwamandla singanyuswa sibe ngaphezu kuka-0.9, futhi amandla asebenzayo angancishiswa kakhulu ngaphandle kwedivayisi yesinxephezelo samandla asebenzayo, engahlangabezana nezidingo zegridi yamandla. futhi wonge izindleko zokusebenza zemishini ekhuphuka nomfula.

- Izindleko zokusebenza kwezisetshenziswa kanye nokugcinwa kwazo zinciphile: Ngemva kokusetshenziswa kokulungiswa kokuguqulwa kwe-frequency, ngenxa yokulungiswa kwejubane lemoto ukuze kuzuzwe ukonga amandla, lapho izinga lomthwalo liphansi, ijubane lemoto nalo liyancishiswa, okokusebenza okuyinhloko kanye nemishini ehambisanayo eyisiza. njengama-bearings aguga ngaphansi kunangaphambili, umjikelezo wokunakekela unganwetshwa, impilo yokusebenza kwemishini inwetshiwe; Futhi ngemva kokuguqulwa kokuguqulwa, ukuvulwa kwe-damper kungafinyelela ku-100%, futhi ukusebenza akukho ngaphansi kwengcindezi, okunganciphisa kakhulu ukugcinwa kwe-damper. Ekusebenzeni kwesiguquli sefrikhwensi, udinga kuphela ukufaka uthuli njalo isiguquli semvamisa, ngaphandle kokuma, ukuze uqinisekise ukuqhubeka kokukhiqiza. Ngezidingo zokukhiqiza, lungisa isivinini se-fan, bese ulungisa umthamo womoya we-fan, ongagcini nje ngokuhlangabezana nezidingo zenqubo yokukhiqiza, kodwa futhi unciphisa kakhulu ukuqina komsebenzi. Ngemva kokwamukela ubuchwepheshe bokuguqula imvamisa ukuze kulawulwe isivinini, ukugqokwa kwemishini kuyancishiswa, umthwalo wokulungisa uyancishiswa, futhi izindleko zokunakekela ziyancishiswa.

- Ngemuva kokusetshenziswa kwedivaysi yokulawula isivinini sokuguqulwa kwemvamisa, injini ingaqalwa ngokuthambile, futhi yamanje ingeqi izikhathi ezi-1.2 zamanje ezilinganiselwe zenjini lapho iqala, ngaphandle komthelela kugridi yamandla, kanye nempilo yesevisi yemoto. inwetshiwe. Kulo lonke uhla lokusebenza, injini ingaqinisekisa ukusebenza kahle, ukunciphisa ukulahlekelwa, kanye nokwenyuka kwezinga lokushisa okuvamile. Umsindo nokuqala kwamandla kwefeni kuncane kakhulu lapho iqala, ngaphandle kokudlidliza okungavamile nomsindo.

- Uma kuqhathaniswa nesistimu endala yakudala, i-inverter inemisebenzi eminingi yokuvikela efana ne-overcurrent, i-short circuit, i-overvoltage, i-undervoltage, ukuntuleka kwesigaba, ukuphakama kwezinga lokushisa, njll, ukuvikela kangcono imoto.

- Ukusebenza okulula nokusebenza okulula. Amapharamitha afana nevolumu yomoya noma ingcindezi angasethwa ukude ngekhompyutha ukuze kuzuzwe ukulawulwa okuhlakaniphile.

- Amandla okuzivumelanisa nokuguquguquka kwamandla kagesi wegridi yamandla anamandla, ububanzi bokusebenza kwamandla kagesi bubanzi, futhi isistimu ingasebenza ngokujwayelekile lapho igridi yamandla kagesi iguquguquka phakathi kuka-15% no-+10%.

Indawo yohlelo lokusebenza

Isikhathi sokuthumela: Dec-04-2023